What if operating your commercial pool could cost less and give swimmers a better, healthier experience? With the right pool sanitation, you can achieve both. Ensuring optimal water quality is essential not only for swimmer safety but also for the longevity of your pool’s infrastructure.

While medium-pressure UV pool systems (or MP UV) have been the traditional secondary and supplemental sanitation choice for controlling chloramines (or combined chlorine) and improving air quality, they come with drawbacks. These systems have high energy costs and operational inefficiencies. In this blog, we’ll explore how switching to Clear Comfort’s Hydroxyl-Based AOP pool systems (advanced oxidation process) can reduce energy costs, enhance sustainability and unlock potential grant incentives.

Understanding Medium-Pressure UV Pool Systems

How Medium-Pressure UV Works

Medium-pressure UV systems use broad-spectrum ultraviolet (UV) light to disinfect pool water, control chloramines and inactivate harmful microorganisms.

As water passes through a UV chamber, mercury vapor lamps emit high-intensity UV light. This disrupts the DNA of microorganisms, preventing them from reproducing and helps break down certain chloramines.

MP UV pool systems are often used to improve air and water quality by reducing mono- and di-chloramines – common culprits of eye, skin, and respiratory irritation. However, they are less effective against trichloramines, the most volatile and irritating form.

Here’s a quick rundown of the MP UV process:

- Exposure to UV Light: Water passes through a chamber illuminated by mercury vapor lamps that emit a broad spectrum of UV light.

- Deactivation of Contaminants: UV light disrupts the DNA of microorganisms, preventing them from reproducing and breaking down chloramines in the water.

- Inactivation of Microorganisms: This process renders microorganisms inactive, reducing their ability to contaminate the water.

Energy Use & Medium-Pressure UV

While MP UV supports disinfection goals, it comes at a high energy cost.

- High Energy Use: Only ~15% of energy is used for water treatment; the rest is lost as heat.

- Cost Implications: Annual energy expenses can range from $3,000 to $12,000 depending on pool size and hours.

- Power for Smaller Pools: Systems for pools with up to 200 GPM filtration rates may consume around 3 kW of power.

- Power for Larger Pools: For 50-meter competitive pools, energy demand can rise to 12 kW.

For many aquatics facilities, this creates long-term challenges for sustainability, utility budgeting, and HVAC load management.

Operating Medium-Pressure UV

MP UV pool systems may seem like the norm, but they often bring high costs, maintenance issues and operational headaches.

1. High Heat & Energy Use

- MP UV systems use a lot of electricity, driving up utility bills.

- Their control cabinets generate heat and often need forced ventilation or added HVAC.

- This increases energy demand and complicates mechanical room setups.

2. Trouble in Corrosive Pool Air

- Pool air contains corrosive chloramines and other VOCs.

- MP UV systems pull this air into their cabinets, risking internal damage.

- Over time, electronics fail and repairs get expensive fast.

3. Ongoing Maintenance Headaches

- UV maintenance often requires pool downtime, leading to schedule changes, lost revenue and unhappy guests.

- Expect regular lamp cleanings and quartz sleeve replacements.

- Control cabinet servicing is also needed to avoid breakdowns.

- These tasks take time and often require trained technicians.

- Over time, repairs or replacements can cost as much as a new AOP pool system.

4. Burns Through Free Chlorine

- MP UV reduces your pool’s free chlorine levels.

- To stay compliant, you’ll use more chemicals and spend more.

- It’s harder to keep consistent chlorine residuals during busy swim times.

Understanding Hydroxyl-Based AOP Pool Systems

In recent years, aquatics facilities have sought more sustainable, low-maintenance and cost-efficient alternatives to traditional UV pool systems. Clear Comfort’s patented Hydroxyl-Based AOP pool secondary and supplemental sanitation offers just that. As a patented and legally protected technology, Hydroxyl-Based AOP is truly one-of-a-kind on the market, delivering an easier, more sustainable approach to pool sanitation.

How Hydroxyl-Based AOP Works

Inspired by how our atmosphere cleans the air, Hydroxyl-Based AOP systems create powerful hydroxyl radicals to oxidize contaminants instantly. These radicals take less than a microsecond to oxidize contaminants in plumbing – never touching swimmers or pool surfaces and equipment.

Unlike traditional UV pool systems that primarily target existing chloramines, Hydroxyl-Based AOP pool systems also prevent new chloramine formation. These AOP pool systems do this by oxidizing organics before they have a chance to react with chlorine. As a result, this patented AOP technology delivers cleaner water and better air quality, working more efficiently than UV pool systems. It’s an eco-friendly, safer solution for pool sanitation that uses less energy, reduces chemical use, and provides superior water quality.

Here’s a quick overview of how Hydroxyl-Based AOP pool systems work:

- System Pulls in Air: Hydroxyl-Based AOP pool systems pull in surrounding air or oxygen (O2) we breathe.

- System Treats Air: Inside the system, oxygen molecules are split into atomic oxygen (from O2 to O1).

- Air Injection into Water: Atomic oxygen (O1) is air-injected into the pool’s plumbing and reacts with water to make hydroxyl radicals that destroy chloramines, microorganisms, and other contaminants.

Energy Use & Hydroxyl-Based AOP

Running a commercial pool shouldn’t mean draining your budget on energy costs. AOP pool systems are significantly more energy-efficient than MP UV pool systems.

- Power Consumption: Hydroxyl-Based AOP AOP systems typically consume 360 to 680 watts (0.36 to 0.68 kW), while MP UV systems require 3,000 to 12,000 watts (3 kW to 12 kW).

- Annual Energy Saving for Smaller Pools: A pool switching from 3,000 watts (3 kW) with MP UV to Hydroxyl-Based AOP could reduce its annual energy cost from $2,890 to $366, based on a rate of $0.11 per kWh.

- Annual Energy Cost for Competitive Pools: A 50-meter pool using 12,000 watts (12 kW) with MP UV could see its annual energy cost savings from $11,563 to $559 by switching to Clear Comfort AOP.

Operating Hydroxyl-Based AOP

In addition to reducing chemical use, Hydroxyl-Based AOP pool systems offer several operational advantages:

1. Fresher, Healthier Air Quality

- AOP systems oxidize organic contaminants and prevent chloramine formation.

- Less chloramine means more refreshing air and water quality for swimmers and staff.

- Fewer volatile organic compounds (VOCs) also reduce HVAC corrosion, extending equipment life and cutting maintenance costs.

2. Lower Chemical Use & Costs

- Unlike UV, AOP handles oxidation, so pools need fewer chemicals.

- Typically, aquatics facilities report 30% to 50% chemical savings.

- More stable chlorine levels help reduce pH swings and slow Total Dissolved Solids (TDS) buildup.

3. Simple, Predictable Maintenance

- Only system maintenance needed is an easy 15-minute cartridge exchange each year.

- Easier chlorine control and water balance means fewer corrections and less staff time spent monitoring.

- Maintain water balance and keep filters clean to support efficient oxidation.

- Unlike UV, AOP system care doesn’t require frequent servicing or pool downtime.

A Case Study: Energy Costs with MP UV & Hydroxyl-Based AOP

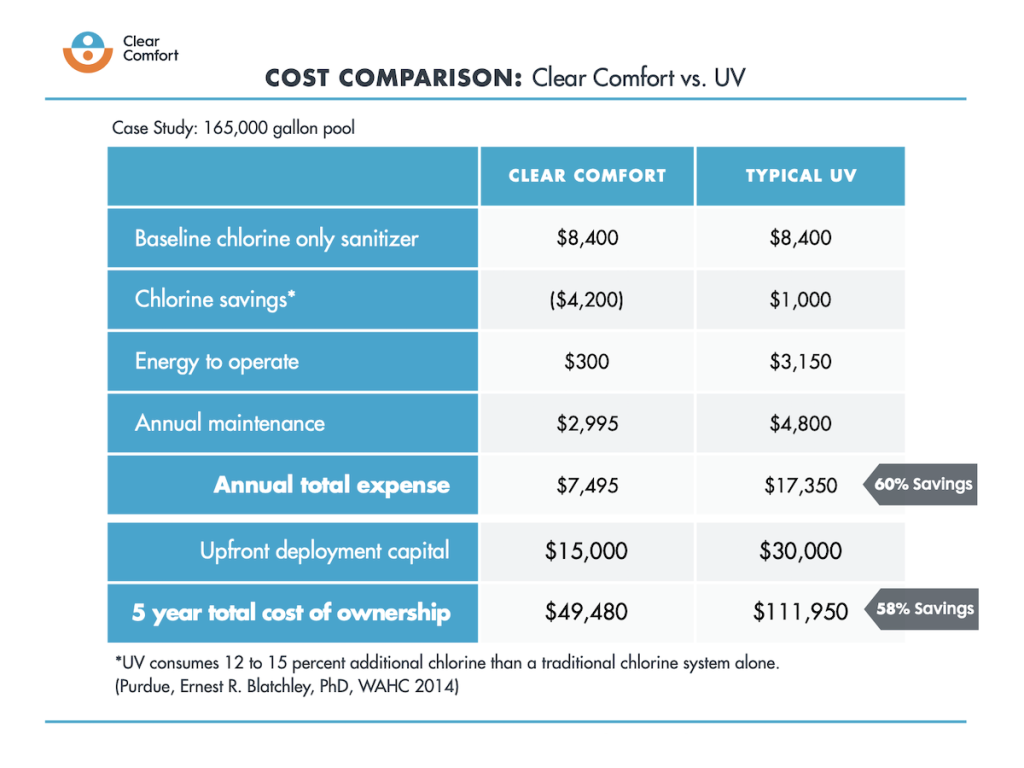

To illustrate the potential savings, let’s compare the annual energy costs for various pool sizes when switching from MP UV to Clear Comfort AOP. This case study on an aquatic facility’s 165,000 gallon pool examines the energy costs associated with MP UV pool systems compared to Hydroxyl-Based AOP systems. By analyzing two different pool setups, we can clearly see the financial benefits of switching to AOP secondary and supplemental sanitation.

Why Are Aquatic Facilities Switching From UV to Hydroxyl-Based AOP?

As today’s commercial pool operators look for more sustainable and cost-efficient solutions, Hydroxyl-Based AOP water treatment systems are leading the way. While both MP UV and AOP pool systems come with maintenance and operational costs, Hydroxyl-Based AOP stands out in energy efficiency, reduced chemical use and sustainability. By switching from UV to Hydroxyl-Based AOP, aquatic operators can reduce costs, save time and enhance the overall sustainability of their facilities.

So why are today’s top aquatic operators making the switch? Let’s explore these four reasons:

- Saved Time on Maintenance

- Lower Operational Costs

- Environmental Sustainability

- Energy-Saving Grants: Cut Costs of Hydroxyl-Based AOP

1. Saved Time on Maintenance

Today’s aquatic operators face uphill battles catering to staff turnover, long to-do lists and health-conscious patron demands – all under budget restraints. When evaluating the switch from MP UV to a Hydroxyl-Based AOP pool system, today’s aquatic operators look at how it saves their facility time, manpower and hassle. Here’s how:

1. Hydroxyl-Based AOP Pool Systems

- Designed for harsh conditions, systems last longer with fewer repairs.

- Only AOP system maintenance needed is an easy 15-minute cartridge exchange.

- Simple maintenance with no special tools, professional training or downtime.

2. MP UV Pool Systems

- Require frequent maintenance by professionally trained service technicians using specialized tools.

- Facility downtime, where the pool is unavailable to patrons, is often necessary for UV servicing.

- Tasks typically involve disassembling parts of the UV pool system, including UV lamp cleaning, quartz sleeve replacement and control cabinet servicing.

- Corrosive pool air leads to more frequent repairs, especially for sensitive components like printed circuit boards (PCBs).

2. Lower Operational Costs

As chlorine and chemical costs rise in a challenging economic climate, aquatic operators are asked to do more with less budget. With resources spread thin, nimble operators have switched from MP UV to a Hydroxyl-Based AOP pool system to save money. Let’s see why:

1. Hydroxyl-Based AOP Pool Systems

- Uses significantly less energy, lowering electricity bills.

- Reduces chemical use by 30%-50%, cutting operational costs.

- No need for additional ventilation, reducing overall energy usage.

2. MP UV Pool Systems

- High energy consumption increases electricity costs.

- Frequent chemical use drives up operational expenses.

- Requires extra ventilation, adding to energy bills.

3. Environmental Sustainability

MP UV pool systems come with high energy consumption and frequent maintenance needs. In contrast, Hydroxyl-Based AOP pool systems treat water effectively and more sustainably, using less energy, less chemical use and minimal maintenance. See how switching to AOP helps aquatic facilities support broader sustainability goals:

1. Hydroxyl-Based AOP Pool Systems

- Energy Use: Lower energy use reduces utility costs and greenhouse gas emissions. No toxic mercury, contributing to a smaller carbon footprint.

- Chemical Use: Reduces chlorine and other chemical use by 30%-50%, lowering costs and minimizing harmful runoff.

- Facility Reputation: Shows a commitment to sustainability, attracting eco-conscious patrons and building trust with stakeholders.

2. MP UV Pool Systems

- Energy Use: High energy consumption increases your facility’s carbon footprint. UV lamps contain toxic mercury, requiring careful disposal.

- Chemical Use: UV systems maintain chlorine levels but don’t typically reduce them, leading to higher chemical use than AOP.

- Facility Reputation: Higher energy use and chemical reliance may not align with sustainability goals.

4. Energy-Saving Grants: Cut Costs of Hydroxyl-Based AOP

Last but not least, many utility companies offer “custom incentive” grant programs to promote the use of energy-efficient technologies. These grants can significantly offset the cost of switching from MP UV to Hydroxyl-Based AOP pool systems.

To help you take advantage of these savings, we’ve outlined the process for applying for energy-saving grants below.

How to Apply for Energy-Saving Grants

To apply for energy-saving grants, you’ll first need to check if your utility provider offers a grant program. Visit their website or contact customer service to inquire about “custom incentives” for energy-efficient upgrades. Once confirmed, you’ll need to provide documentation demonstrating the energy savings from switching to an AOP system. Review your utility provider’s specific grant requirements, as they may vary.

Here’s what you may need:

- The model number of your existing UV system.

- The flow rate (GPM) of your pool’s filtration system to determine the correct AOP system size.

- Details about your electricity usage and your utility provider’s information.

Understanding grant funding can be challenging. Our team is here to guide you through every step of the process. Sign up to get free help applying for energy-saving grants, here now.

Embrace Energy Savings at Your Aquatic Facility

Switching from MP UV to Hydroxyl-Based AOP pool systems isn’t just a smart move — it’s a game changer for your aquatics facility. By reducing energy consumption, lowering chemical use and cutting operational costs, you’re saving money and making your swimming environment healthier for your patrons and staff.

If your aquatics facility uses UV, look into upgrading to Hydroxyl-Based AOP water treatment with the help of energy-saving grant funding. Your decision makers, patrons and staff will thank you for it.

Ready to see how much you could save?

Sign up for a free consultation, and our team will help you apply for energy-saving funding to switch to Hydroxyl-Based AOP water treatment for your pool, spa or waterpark. Get started now. »

Krystalanne Curwood

Gabrielle Palumbo

Marketing Director